Titanium racks have long life because they are not consumed by the chemistry and they do not need stripping after anodize. They can be specially designed with a variety of fingers, titanium clips, titanium discs, and other contact points, and be sized to maximize the volume of parts that can fit in a tank. They can also be designed to hold the part for superior rinsing and drainage, and protect the part from damage during travel. Consequently, a well designed rack is an effective way to improve process capability (ie, better quality), lower finishing costs by increasing tank utilization and avoid stripping requirements, and produce faster turn times by maximizing loads while designing the tooling for quick racking and unracking.

TITANIUM DISC RACKS – Please see PDF’s below for different styles.

STANDARD NOTCHED TIP -TYPE D DISC PDF

STANDARD RIGID BOTTOM – TYPE DX DISC PDF

STANDARD PERMA-FLEX – TYPE DP DISC PDF

STANDARD TAPER TIP – TYPE DTL DISC PDF

STANDARD FLAT SLOTTED FINGER – TYPE DF DISC PDF

STANDARD WIRE PIN – TYPE DW DISC PDF

SPLINES & HOOKS – Please see PDF’s below for Splines and Hooks.

COLLARS – Please see PDF below for different styles

BOX RACKS

Space Saver, Perma-Flex, Double Rail and Piano Racks are available

UTILITY RACKS

2-way and 4-way racks are available with assorted designs.

TITANIUM CLIPS & CLAMPS – Please see PDF below for different styles

FASTENERS – Please see PDF below for different types and sizes

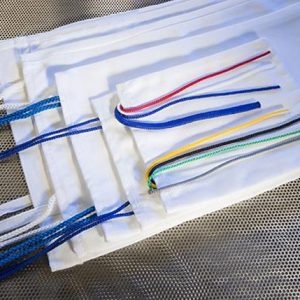

BULK ANODIZE BASKETS – Please see PDF below for details.

BULK ANODIZING BASKET – STYLE LTL PDF

HI-LODE RACKING SYSTEMS

Assorted designs and sizes are available

Please contact us with your requirements and we will provide pricing and / or additional information.