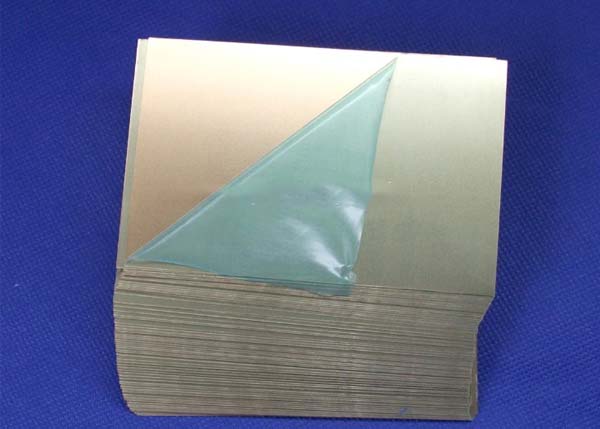

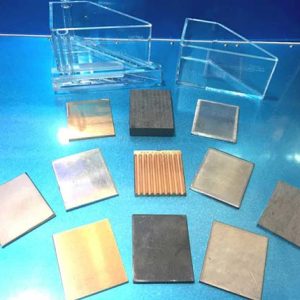

Hull Cell Panels or Cathode Panels – There are many sizes and basis materials. In the printed-circuit industry, specific non-conductors are readily obtainable, pre-coated. Standard panel size is 7 by 10 cm. The “Jiggle cell” panel is approximately one inch wide by eight inches long before forming.

Having obtained the anodes, bags and cathode panels required, you’ll need some additional laboratory equipment to do the most effective and accurate testing.

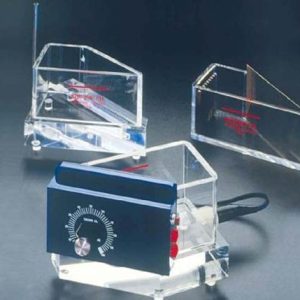

The Hull cell is a time saver. Hull-cell panels are inexpensive when compared with experimenting in a production tank plating actual parts. You can introduce variables quickly and safely in the small tank represented by the cell. And you can see the results of several different tests at the same time.

The cell holds 267 ml of plating solution. At that volume, there are direct correlations of milliliter or gram additions to 100 gal of plating solution, without the need for a math degree. A 2-g or 2-ml addition to the 267-ml cell equal an addition of 1 oz/gal in your operating bath.