Plating Lines – Automated & Manual

Plating lines can be either manual or automated. Manual electroplating machines are suitable for precious metal plating, such as nickel, silver, gold, etc.. Manual electroplate machinery has features of design layout flexibility, small footprint, can have both 2 to 3 processes, which is a plating process that can meet a variety of parts production needs.

Semi-automated electroplating machines are suitable for precision electronics, small hardware pieces of mass production, and the output value is large, with good economic returns. The electroplating production lines is set up on rails to feed traffic on the production line, the travelling crane runs on rails to transport workpieces for processing in the coating bath, and workers hand control the driving with a push-button. The semi automation electroplating machine has been designed for the speed of the travelling crane, the lane and hook, as well as the workpiece quantities and area, also it includes the production cycle and process parameters. So has the advantages are high product quality, good consistency, high output, and the design load factor can reach higher production rates!

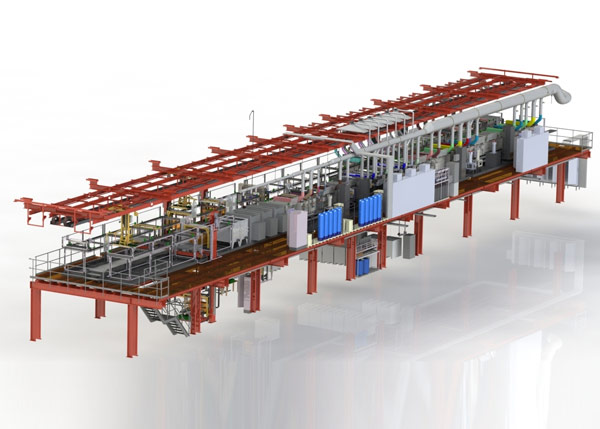

Automated electroplate machine lines (automatic barrel plating line or hanging tool type) are according to a certain electroplating processes that combine the plating tank, electroplating enhance conveyance device, electrical control devices, power equipment, filtration equipment, testing equipment, heating and cooling equipment, air agitation equipment portfolio as a whole. Through the mechanical and electrical installation to automatic fulfillment, the electroplating whole process produces high production efficiency, and consistently high product quality.