Have any questions? Our friendly and professional

staff can help you. Contact us today!

Email: info@alertsales.com

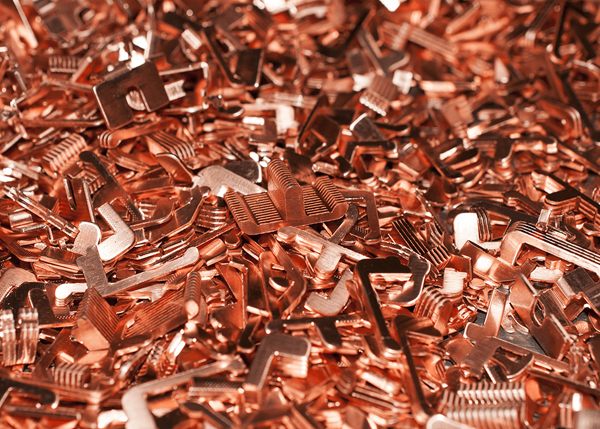

Copper

ACID COPPER – Sulfuric acid-based copper plating processes quickly and efficiently produce low-stressed, ductile, bright copper deposits. The additives are designed to operate at bath temperatures of 75 – 100o F (24 – 38o C) without any noticeable loss in quality. This allows for faster deposition rates with fewer defects.

The outstanding features of bright acid copper processes are:

• Fast plating rates at higher current density with lower burn

• High deposit brightness, exceptional rates of brightening and leveling, and no loss of ductility

• Ease of bath maintenance and control under production conditions

• Replenishment based on ampere-hours and controlled by Hull Cell tests.

• Wide operating temperature range

ALKALINE NON-CYANIDE COPPER – This process is engineered for use on all commonly used metal base materials, including zinc die-cast. The process exhibits exceptional throwing power and adhesion on complex part geometries. It produces a semi-bright copper deposit that is suitable either as a strike or main copper layer for nickel and chromium plating

PYROPHOSPHATE COPPER PLATING – This process can be used in place of cyanide or acid copper in a wide variety of functional and decorative applications including electroforming and plating on properly prepared zinc-based die-castings and aluminum.

Advantages of the process are:

• Fully bright deposits over a wide range of current densities

• Good leveling properties

• Excellent throwing power

• Non-corrosive to parts and equipment

• Simple make-up, using liquid concentrates

• Easy to control brightener system

• Does not produce immersion deposits on steel parts

CYANIDE COPPER – Cyanide copper plating processes offer ease of control and bright, ductile and economical leveling properties over a wide range of current densities and plate thicknesses. Advantages are:

• Particularly suited for deposits over zinc base die-castings

• Deposits have excellent buffability properties.

• May be used with direct current or for higher deposition rates with interrupted current or periodic reverse

IMMERSION COPPER- processes provide a uniform deposit with exceptional adhesion. The process allows for subsequent acid copper treatment without the need for a nickel strike and helps to plate large and complicated shaped plastic parts. Based on the application,

Please contact us with your requirements and we will provide pricing and / or additional information.