Have any questions? Our friendly and professional

staff can help you. Contact us today!

Email: info@alertsales.com

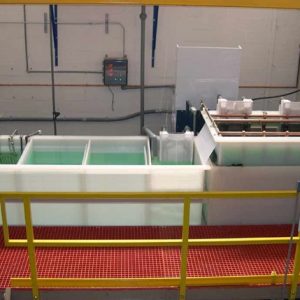

Steel & Stainless Steel Bright Dips

Laser FE is a room temperature, hydrogen peroxide-based immersion chemical polishing process designed to provide bright steel surfaces. It may also replace vibratory mass finishing of carbon steels. Benefits of using Laser FE in place of vibratory mass finishing include an extremely short process cycle and no loud or expensive vibratory bowls. Laser FE is based on environmentally friendly hydrogen peroxide.

Click on TDS below:

Stainless Steel Brite Dip NI is a liquid acidic product, free of fluorides and chromates which will brighten and passivate 300 series Stainless Steel, Monel and Kovar. While the Stainless Steel Brite Dip NI will not brighten the 200 and 400 series Stainless Steels, it will provide a passivated surface for improved corrosion resistance

Click on TDS below:

Stainless Steel Bright Dip TDS

Please contact us with your requirements and we will provide pricing and / or additional information.

*Due to restrictions and/or hazmat regulations this product cannot be ordered on-line.